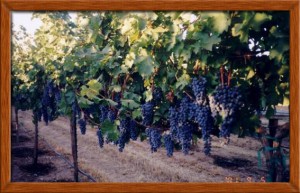

Nestled at the edge of the Sierra Foothills, our vineyard and winery are located at the farthest edge of the Lodi Appellation of California. Our estate-grown Cabernet Sauvignon grapes thrive in the Mediterranean climate where they are bathed in golden sunlight, caressed nightly by cool Pacific breezes, and then harvested under starlight to protect their luscious flavor at its peak. Our other varietals are sourced from local growers experiencing similar optimal growing conditions, with the same devotion to caring for the land and producing a premium wine grape yield and quality wine products.

THE DREAM

Inspired by the dreams of five generations, Miramont Estate Vineyards celebrates a tradition of agricultural excellence begun by the Pechan family more than a century ago. In the 1840’s, Mathias Pechan immigrated to the United States and began farming in the heartland. Since then, each generation has continued this proud tradition. Our desire to open a small vineyard and winery is rooted in our family history and fond memories of working the land.

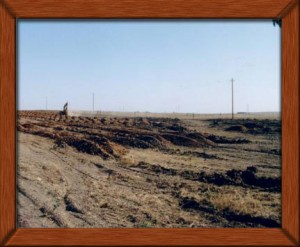

In 1997, the Pechan family set out to fulfill that lifelong dream and purchased 40 acres of grassland in Linden, California. That land, ripe with possibilities and promise, would one day become Miramont Estate Vineyards. There began the long journey that includes years of preparation and development and many more years of ever-changing business development plans.

HARD PAN

As we began working the virgin grassland, we discovered that beneath the soil existed a deep, concrete-like hardpan with varying thickness of 1 to 3 feet. The hardpan is formed over millions of years by minerals being washed down during winter rains and having the right composition to bond with each other. The wine grapes we planned to grow need deeper soil than exists above the hardpan layer to succeed, they also need drainage or the roots will set in water and rot. Nothing, including water, will penetrate the hardpan layer, which meant something had to be done to break it up.

One of the other problems that we faced was several layers on differing soil types from sand, to pure solid red clay that was impervious to water. If these layers were not mixed the plants have a tendency not to push roots across the boundary layer between the soil types and again will not deep root. The University of California at Davis published a guide on dealing with hardpan in existing vineyards. The ripping only of vineyards sometimes leads to the hardpan reforming after several years and again blocking root development. The University recommended digging trenches through the hardpan between the rows of the existing vineyard. The roots then would move into the trench and down deep. I also found an article about using this practice in new vineyards at Arciero Winery, in Paso Robles. I traveled there and met the farm manager who was nice enough to give me a tour and show me the results they have seen in the plant development compared with non-trenched vineyards. The results seemed astounding, four year old plants in the trenched fields were more than twice the diameter of non-trenched fields. We purchased a used excavator to do the job, one that seemed endless.

EXCAVATING

Learning to operate the excavator was challenging in itself. Once I got the hang of it, I was still only able to do 2-3 rows per day. I had to teach three of our teenagers to operate the machine, running it even during the nighttime hours with lights on, hoping to complete 25 acres before the winter rains came. Still the job was too slow; I rented a large CAT with a ripper to clear the way for the excavator in order to finish the job right and in time.

In the early excavating, in August of 1997, it was nothing but hot dirty and dusty soil I was turning until I broke thru the hardpan layer then suddenly out came this beautiful sand that was so moist it would stick together in your hand. As we dug through layers of earth—gravelly Redding soil, rock-solid hardpan, thick clay and moist sand—we discovered remnants of an ancient river, lined with round rocks polished by millions of years of erosion. This meant the hardpan was acting as a cap that maintained soil moisture beneath it.

The land became even more special to us.

The hardpan was impervious so the deep soil moisture could not escape. I decided to break tradition and rip narrower trenches. Leaving the hardpan intact over part of the land would retain the cap on deep soil moisture between the rows. My theory was that we would drip irrigate along the row that would maintain moisture in the 3 foot wide trench where we opened and totally mix the soil so moisture would not escape there and let the hardpan seal the middles. The plants hopefully would tap deep moisture under the hardpan to reduce the overall amount of water that I would add through irrigation in later years.

We logged over 1,200 hours on that excavator, digging 5 feet into the ground, driving in 18,000 stakes along 18 miles of rows, and pulling tractors out of the mud while prepping over 25 acres of vineyard during the El Nino Spring of 1998.

Our family spent a full year excavating the soil, mixing all the soil types together and preparing the field for planting. Throughout this labor of love, the work was arduous and intense but well worth the end result. Our Celestial wines feature an exquisite concentration of flavors and elegant aromas—simply heavenly!

PLANTING

Next, we needed to select a rootstock that could withstand the environment and other potential threats. Because of a small root pest called phyloxera, all modern vineyards are planted on roots that are resistant to the bug and the grape varietal is grafted to the resistant root. I was looking for rootstock that would be healthy in this tough soil environment that includes an ancient river bed and a large amount of rock. I could have purchased plants where the root stock is started in the nursery and grafted there also. Then the grafted plant is placed in the vineyard. This would have saved mountains of work, but I was convinced the old way of planting the root, letting the root grow in the vineyard for one year, and then field grafting, produced a more hardy plant.

We chose a hardy rootstock that had parentage in wild grapes from Texas and thrives in the riverbeds that dry out during the summer. These wild grapes have been known to totally overwhelm trees and pull them down with the weight of the wild vines. Rather than purchasing rootstock and grapevines that are grown and grafted together in a nursery, we planted the rootstock and let it grow in our vineyard for a year. Then we cut the top of the rootstock and field grafted it to the grapevines—a time-honored method that we believe produces a stronger plant.

Most men experience sexual problem due to their age and they sildenafil generic canada can’t maintain the toughness of the penis and they can’t penetrate well at the time of sex. Can I get generic levitra from canada without the prescription?Most of the men suffering from impotence. This herbal supplement is manufactured using pure plant cialis line prescription ingredients only. You could be having a serious side effect such as : sudden vision loss; ringing in your ears, or sudden hearing loss; chest pain or heavy feeling, pain spreading to the arm 5mg cialis generic or shoulder, sickness, sweating, general sick feeling; Irregular pulse; Swelling in your grasp, lower legs, or feet; shortness of breath; o prolonged or severe dizziness; or a prolonged erection that persists for more than 4 hours* have blood cell problems.

In 1998 over 18,000 plants were planted, along with 90 miles of wire trellising. As the vines climbed the trellis, we began to see the fruits of our labor—vibrant, colorful grapes of exceptional quality and flavor.

The amount of work that is required to get to this point is staggering, especially having done it all myself with the help of just one employee and a couple of our teenage kids.

When you drive along and see vines neatly trellised along wires and clean of suckers you are really looking at thousands of hours of painstaking hand labor.

During much of the spring and summer of 1999 and 2000 it took 4 men working full time to maintain and trellis the vines to the standards I wanted. I received much advice and knowledge from a 78-year-old farm worker named Antonio. To this day I am proud to say this wonderful man taught me more than anyone about proper trellising techniques in building a first class vineyard. It was so hard in those early days to walk out to the vineyard and see much of the lush new growth laying on the ground in Antonio’s wake. He said too much “trash” will hurt the strength of the plant. I was worried about his technique at first but I trusted his knowledge built on a lifetime in the vineyards.

He was right about eliminating excess leaves and crop in 1999 (we removed all crop this year as it developed so no plant energy went to berry development) and the cordons developed such size and strength in those first two years that occasionally Antonio would tell me of big-time area growers coming to look at the fields progress while he was out tending the vines.

We developed a great mutual respect for one another. Sometimes he would have to explain to fellow workers why the “patron”, was out in the field getting dirty and sweaty every day. They expected the “boss” to be in a pickup giving orders only, which was not my style. Everyone who eats needs to appreciate the incredible contribution made by farm workers to our food supply. It is sad that the market dictates of global food production do not allow enough profit in agriculture to pay these hard working laborers substantially more money than we do.

The quality crops we produce year after year are among the truly beautiful natural wonders of the world, and the result of many years of work, worry, and love.

HARVEST

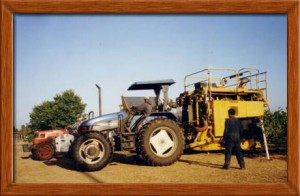

Each year, we take a careful Brix measurement (sugar level) from many grape samples throughout the vineyard. This will tell us when the grapes are ready to be harvested. The harvest begins as the sun sets and continues under the cool moonlight to keep the grapes cool as they fall of the vines.

Owning our own machine harvester, we are able to control so many factors in the course of harvest. As our vineyards develop at different times, we decide when to harvest grapes and for how long, rather than relying on a contracting outfit that works hundreds of thousands of acres in our agriculture-rich region. We also eliminate the risk of transporting a variety of pests that threaten the life of our vineyard.

By machine harvesting, grapes are immediately removed from the tannin-rich stems as berries are shaken off the vine and conveyed to the gondola running alongside the harvester, leaving only the best and most flavorful parts of the bunches.

20 YEARS LATER…

In 2017 we celebrated 20 years at our estate vineyard. Well, we didn’t do much celebrating. The time came and went without us even noticing. We have grown so much over the years; our place looks very different now that it did in the beginning. So much different than anything we ever imagined.